Effective warehouse management is crucial for businesses looking to streamline operations, optimize inventory, and minimize costs.

However, many businesses overlook the potential consequences of poor warehouse management until it is too late.

In this post, we’ll highlight five key inefficiencies in warehouse operations that can cause significant disruption and contribute to increased overhead expenses—and how addressing them can help your business optimize its warehouse processes.

1. Inefficient Inventory Management

Inventory management is at the heart of warehouse operations. Poor inventory management leads to overstocking or understocking of products, which can result in wasted space, lost sales, or excessive storage fees. When inventory is not properly tracked, businesses are also at risk of losing valuable stock, leading to missed opportunities and unnecessary restocking costs.

Inaccurate inventory management can also create problems with order fulfillment. If stock is not correctly recorded, it may delay shipments or result in incorrect orders being sent to customers. This kind of inefficiency increases the likelihood of returns and customer dissatisfaction, both of which add to operational costs and harm customer relationships.

The latest warehouse management services offer advanced tracking systems to ensure your inventory is always up-to-date and accurate, helping to avoid unnecessary expenses. Wareouse inventory solutions help streamline inventory management, reduce stock discrepancies, and prevent overstocking or stockouts that can hurt your bottom line.

2. Poor Space Utilization

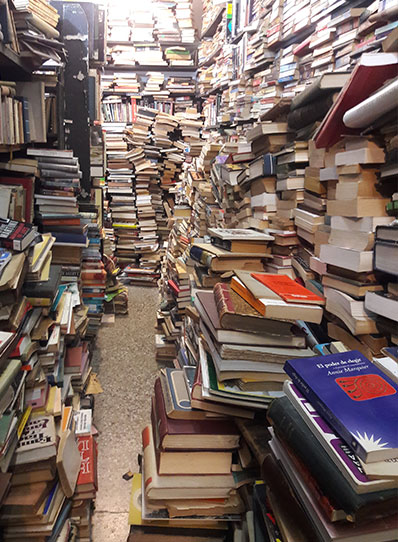

Underestimating the importance of space in your warehouse can lead to operational inefficiencies. Poorly organized warehouse layouts and improper shelving systems waste valuable square footage and create roadblocks across departments, from receiving to picking and shipping.

When inventory isn’t organized in a way that optimizes the available space, it can lead to congestion and delays in locating products. This reduces efficiency and adds unnecessary labor costs as employees spend more time on the hunt, ultimately creating headaches in order fulfillment.

Choosing a provider that specializes in optimizing warehouse layouts can increase efficiency and help businesses design effective shelving systems and workflows that enhance productivity and make the most of available space, reducing unnecessary costs and getting orders out the door.

3. Lack of Technology Integration

In today’s fast-paced business environment, technology is key to improving warehouse operations. The absence of automation or the use of outdated systems can cause inefficiencies that slow down workflow and increase manual labor costs. Without integrated systems, businesses struggle to manage inventory accurately, leading to mistakes and delays that can trickle down into customer service issues.

Technology, such as barcode scanners, warehouse management systems (WMS), and automated inventory tracking, can vastly improve the speed and accuracy of warehouse operations. Without these systems in place, the cost of manual handling and the risk of human error is significant.

4. High Employee Turnover and Low Productivity

High employee turnover can result in increased training costs alongside productivity challenges in the warehouse, which can result from a poor culture, inadequate equipment, or unclear processes, all of which drive up operational costs.

Investing in proper training, creating efficient workflows, and providing employees with the tools they need to do their jobs are key to improving both retention and productivity. Failure to do so leads to longer hiring processes, constant retraining, and reduced output—all of which eats away at your bottom line.

5. Inadequate Safety Measures

Safety in the warehouse is not a part of your operations that can be overlooked or put on the backburner. Safety hazards such as poorly maintained equipment, cluttered aisles, or inadequate safety protocols not only increase the likelihood of accidents but also damage morale and increase downtime.

When safety is neglected, businesses face the risk of legal consequences, damage to reputation, and expensive medical claims. Additionally, frequent accidents and injuries slow down productivity, adding extra costs for both labor and lost time.

Have More Questions About Choosing the Right Warehouse Provider?

Our experienced team can help. Get your free consultation today!

Learn MorePartner with Corovan for Efficient Warehouse Management

With over 75 years of experience, Corovan is your trusted partner in maximizing warehouse productivity and minimizing operational costs. Let us help you unlock the full potential of your warehouse and improve your bottom line. Contact us today.